Why Standard Brake Parts Don’t Work for Special Vehicles

Special vehicles such as construction machinery, mining trucks, port equipment, agricultural machines, and military vehicles often operate under extreme conditions and require brake systems beyond standard specifications.

Common Challenges:

- Incorrect fit: Standard brake parts rarely match non-standard vehicle dimensions.

- Harsh environments: Heavy loads, high temperatures, dust, and moisture demand higher protection and durability.

- Obsolete components: OEM parts are discontinued, making replacements difficult.

When your vehicle stops, your operations stop. That’s why a customized brake solution is essential for safety and efficiency.

Our Solution: Sample-Based Customization

We specialize in custom brake solutions based on your physical sample, delivering precise fit and reliable performance.

Our Services Include:

✔ Reverse Engineering: High-precision measurement and modeling of your sample to ensure exact replication.

✔ Protective Surface Treatment: Options such as electroplating or anti-corrosion coatings to enhance durability.

✔ Interface Optimization: Customized mounting holes and connection structures for seamless installation.

✔ Fast Delivery: Sample-based development reduces production time, minimizing vehicle downtime.

Technical Highlights

- High-precision 3D scanning & CAD modeling – guarantees dimensional accuracy and perfect fit.

- Advanced machining processes: CNC precision manufacturing ensures consistent quality and tight tolerances.

- Surface protection: Electroplating, anti-corrosion, and durable coatings suitable for mining, port, and harsh environments.

- Custom interfaces: Tailored mounting solutions for special vehicle requirements.

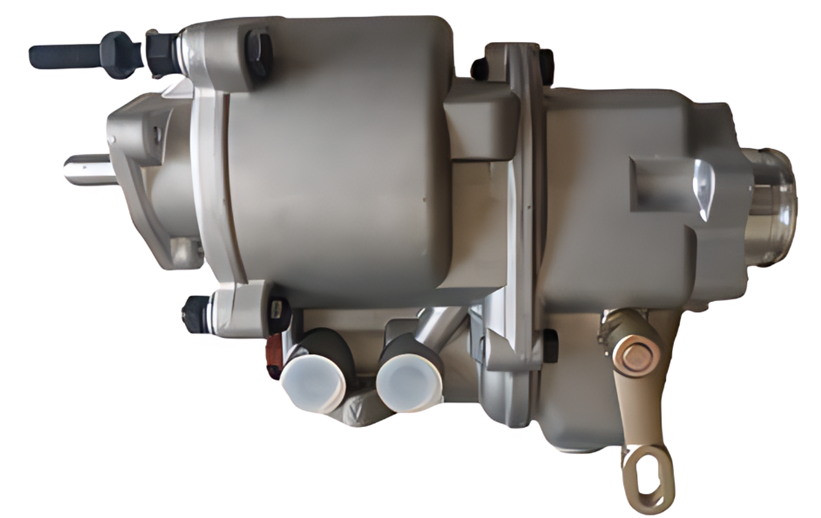

Case Study: Heavy-Duty Mining Truck Brake Solution

Client Challenge:

A mining company operating at high altitudes needed a replacement brake chamber for a heavy-duty truck. The original OEM part had been discontinued, and standard alternatives did not fit the vehicle’s unique configuration.

Our Approach:

- Collected the original sample from the client.

- Conducted 3D scanning and reverse engineering to replicate the exact dimensions and structure.

- Optimized mounting interfaces for seamless installation.

- Applied anti-corrosion electroplating to ensure durability in high-humidity, dusty environments.

- Delivered the customized brake solution within 20 days, minimizing vehicle downtime.

Result:

- 100% fit compatibility

- Enhanced protection and extended service life

- Avoided costly downtime, improving operational efficiency

Why Choose Us?

✔ Extensive experience in special vehicle brake customization

✔ Expertise in urgent orders and obsolete part replacement

✔ Full technical support from design → sample development → precision manufacturing → delivery

Industries We Serve:

Mining | Construction | Agriculture | Military | Port Equipment

Your Sample, Our Expertise

If you have a brake sample, we can transform it into a high-performance, precisely fitted solution tailored for your special vehicles.

📩 Contact us today to start your customized brake project!